Tungsten Vs. Chromium Carbide Recharging

BYG, experts in adaptable spare parts, we help you choose between tungsten and chromium carbide to improve the durability and performance of your machinery.

Tungsten, represented by the symbol W and atomic number 74, is a dense, silvery-white, brilliantly luminous metal with ductile malleability. Recognized as the densest element among its native peers, tungsten exhibits outstanding resistance to heat and corrosion, making it one of the most robust elements in these properties.

As for chromium carbide, with its formula Cr3C2, it presents itself as a solid substance, characterized by its outstanding hardness and heat resistance. This versatile compound plays a crucial role in a variety of applications, from cutting tools to coatings and friction materials, highlighting its essential presence in industry.

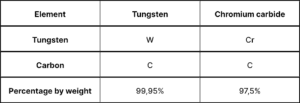

Table with chemical composition:

Tungsten Hardfacing: Hardness and Longevity

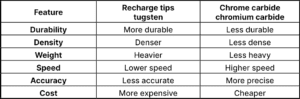

Tungsten hardfacing tips, known for their exceptional hardness, offer superior wear resistance and can withstand intense punishment. Its density, being the highest among the native elements, allows a greater amount of energy to be transferred to the target. However, their additional weight can be a crucial consideration.

Chromium Carbide Reloading: Lightness and Accuracy

Chromium carbide reloads, based on the compound Cr3C2, are noted for being lighter and more accurate. Although they cannot withstand the same amount of punishment as tungsten, their lighter weight makes them a valuable option for situations that demand precision and maneuverability.

Table summarizing the differences between tungsten and chrome carbide hardfacing tips:

Choosing Wisely for Every Need

The choice among these hardfacing materials will depend on the specific nature of the job. For projects requiring extreme durability and strength, tungsten hardfacing is the obvious choice. On the other hand, when precision and light weight are a priority, chromium carbide hardfacing will stand out.

Ultimately, the battle between tungsten and chromium carbide is a matter of balance: strength versus maneuverability. The industry decides, and each choice carries with it the promise of exceptional performance in its particular domain.

In short, BYG offers not only quality adaptable spares but also the possibility to customize the choice of reloads to each customer’s specific needs. In this competition between tungsten and chromium carbide, BYG guarantees exceptional performance, regardless of the choice. Heavy machinery has never been so efficient and versatile.

Attached is a complete hardfacing table for bimetallic steels, where you will find precise details and options adapted to your needs.

HARDFACING TABLE FOR BIMETALLIC STEELS

For more information about tungsten and chromium carbide hardfacing, please do not hesitate to contact our team by phone at 911109111.